A couple are 3/32" but most are 1/16" or smaller.

Ah yeah scratch my filler plate comment. You’ll be fine as you’re doing with those gaps.

For the 3/32” gaps, AWS D1.1 technically says fillet weld legs are to be increased by the size of the gap.

That being said, D1.1 is for steel and way overkill for the typical boat/skiff world.

So cool watching this come together.

There’s still time to weld a 2x4 down the center for extra performance. ![]()

That 2x4 is legendary…don’t let it die!

You’ll want those gaps to be as non existent as possible. Tacking with a 1/16” gap is super easy, running a bead with a 1/16” gap and a spool gun not so much.

Also, something I’ve done on the last couple boats is i weld only on the non visible side of the bulkheads. That way when you’re inside the boat all you see is the super tight fitup of the panels and no welds. Makes it feel less like a welded aluminum boat. Food for thought.

Also, nice Zinc annode on the transom will take care of you. I also recommend painting inside the foam compartments with some good self etching primer or epoxy primer. Anything to help reduce possibility of corrosion in the areas you can’t get to to rinse out very well later on.

Thanks for the input, Bob. I appreciate the preview of coming attractions! ![]()

Sorry guys, work disrupted my schedule for a while. Don’t worry, my boat didn’t fall on me or anything! ![]()

I plan to spend the next month or so going on a side quest. I’m going to work on a linear motion base to rest on while putting in mig welds. It’s essentially one-third of a 3D printer, but I’ll be printing with molten aluminum instead of plastic.

Working on getting all my ingredients together for development. This week I extended Wi-Fi coverage into the shop.

Sounds pretty hi-tech I cannot wait to see this.

Man, I was all hyped up to see some long welds. Just ribbing! Thanks for the update, now I can get back to jet ski flats boat drama ![]()

I was beginning to think I lost the thread. No pressure but cmon man you can’t just drop us like that..![]()

![]()

I’m going to start referring to my shop as the “Department of Naval Awesomeness”.

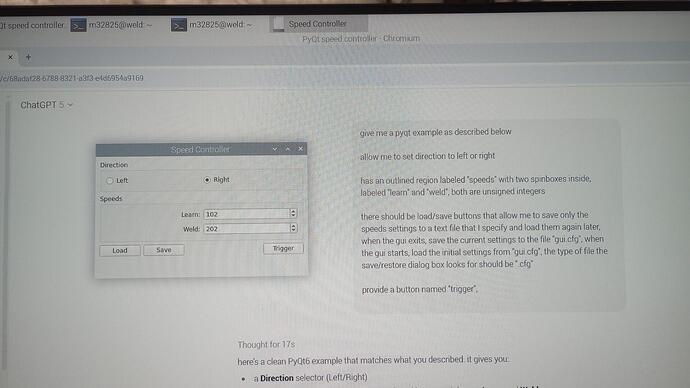

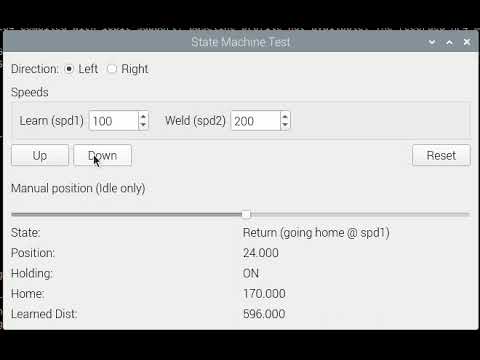

Getting started on a motion base for putting in welds. Using ChatGPT to create a gui. Next step is to tie in motion control.

Looks like the DNA is getting pretty hi-tech. Keep it coming watching intensely.![]()

Nice shop name!

Brainstorming operation…

There will be a physical switch to select left or right movement. I’ll have the ability to tweak speed settings on the gui. Once they are dialed in I can have a button press to load a configuration (e.g. outside corner).

I want to control most of the use with the spool gun trigger switch. The state of the switch will go to my controller and the signal that the welder should weld will come from it. Initially the holding current will be off and, allowing me to position the motion base manually. When I press the trigger the system will note the beginning location and the motion base will begin moving in the selected direction at the “learn” speed. When I release the trigger the motion base will return to the beginning at the “learn” speed and holding current will stay on. When I press the trigger again, the motion base will traverse the same distance but at the “weld” speed while the welder is commanded to weld. At the end of the move the welder stops and we go back to the initial state with holding current off. At any point a “short click” of the trigger resets to the initial state.

I want to see a video of it when its working! Wow!

That’s sounds impressive, and I agree, I want to see it in action.

Definitely got to see this in action. ![]()