Intro TBD.

Looks amazing!!

A beast of a machine, for sure!!

Amazing work!

Incredible planning and execution. There are some really talented builders on here. Very impressive!

Next step is to TIG weld the open corner joints around the transom. Then I’ll do the first couple inches of every joint that ends on the transom.

Practicing outside corners. The center seam was vertical, outsides were horizontal. I’m working on getting more consistent penetration.

Very cool. Keep the progress reports coming!

Literally looks like a stack of dimes. Nice!

Impressive craftsmanship!

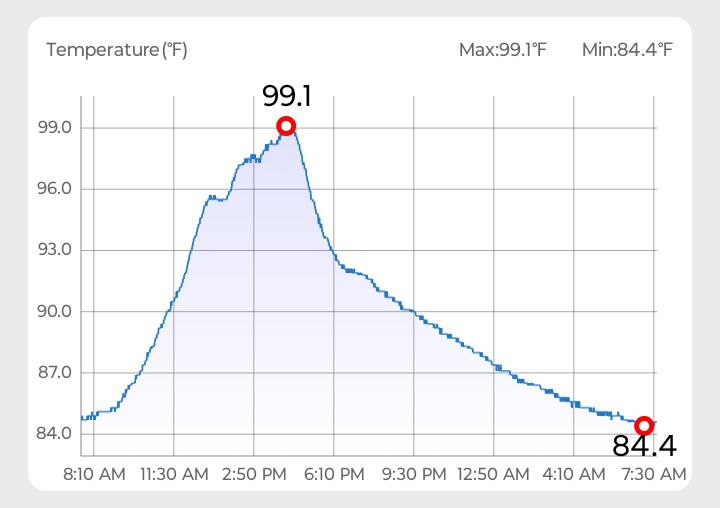

My shop temp is solidly in its summer pattern. Hard to get excited about spending time there. A few hours first thing in the morning are okay.

That thing is looking slick. I’ve welded all my life and my stainless/carbon tig skills are solid, but Alum is another animal. It’s one area that I haven’t had much experience with until recently, so I can one hundred percent appreciate your beads. Great work.

Great work, really enjoying your build.

The heat….yea that’s why I immigrated to BC Canada… they provide FREE air conditioning 24-7 up here. Been a game changer for me not getting cooked anymore. It got so hot here yesterday I switched to wearing shorts and a tee shirt for 3 hours from 2:00 -4:00 pm while I build my roll over cradle for latest build.

Looking good Carl! I could eat off your work surfaces

That’s all of the horizontal open corner on the transom, vertical is next, then I’ve got a fillet where the transom meets the sheer flange.

Wow I don’t know anything about welding but that looks very nice however it must be tedious especially for the lengths you have to weld!