True story…My wife and I made the 500 mile trip down to Cape Canaveral in May 2010 to watch the shuttle launch. The launch was almost scrubbed because they found a loose ball bearing near the launch vehicle. The launch went off after a few minutes delay, if I remember correctly.

Oh, I remember now. I wanted to repurpose a bearing inner race for something. That one got away during disassembly.

I agree with smack, the lines on it look great!!

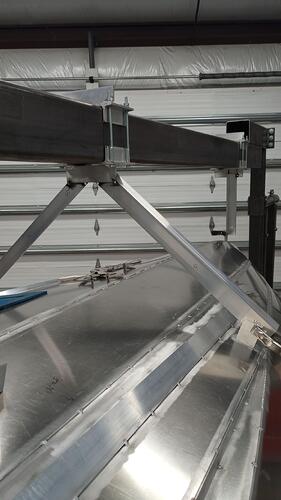

Carl…I don’t think I’ll ever tire of looking at this hull in aluminum. Looks amazing!

I understand the concept of developable surfaces, but when you see a bunch of flat sheets of aluminum turn into that shape you start thinking magic must be involved.

That’s a really cool rotisserie your building. I’m jealous of your shop for sure. I always wanted to build an aluminum skiff, but will settle for watching yours come to life.

Looking damn good!

Impressive!

I am impressed with your confidence in tack welds…I tend to be a “the more the better” or “three fasteners means use the whole box” approach. I could see myself welding everything out just because it would help me sleep better at night!

I tack it, then pull it down and weld everything I can reach. Each joint is only holding about 80 pounds, but if you can’t weld good, weld lots! ![]()

I’m an over build it guy myself, but I learned the hard way, as I do with most things, when it comes to tack welding alum or any sheet metal panel less is more.

That’s a really good point: the weld needs to be appropriate for the purpose. More is not always better.

For hull panels, everything gets fully tacked before any seams are welded. When they are welded, the bead needs to be a little more than the thickness of what you’re welding. The bigger you go the more heat distortion you create.

For attaching pieces of 2x2x1/4" aluminum angle together, hammer down.

Awesome man!!! I know that has to be rewarding.

We have liftoff!

That had to be an exciting moment, congrats! Your skill and patience is something to be spoken for. I cant wait to see what’s next.