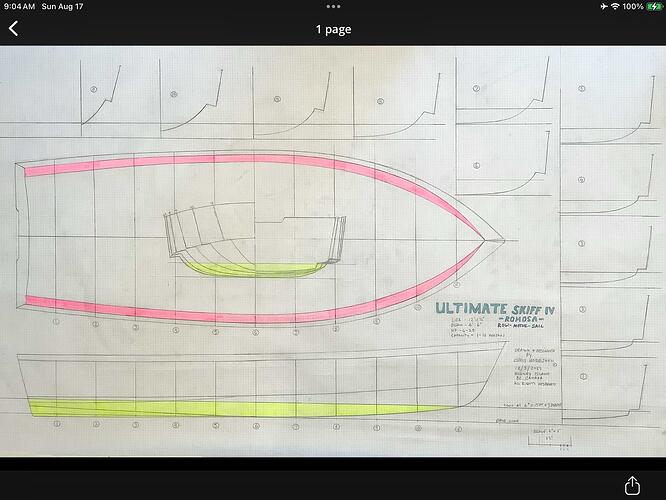

Old sailing friends sent me these two photos of the 12’3” ultimate skiff I built 32 years ago. They are anchored in the south of England right now waiting for a weather window to cross the Bay Of Biscay and over to Spain. They will leave Monday, and have brought along a box of firecrackers to help dissuade the possible pissed of Orcas from messing with their rudder as they past the northern tip of Spain.

I built this dinghy/ skiff for other friends to fit on their sailboats cabin top. In order to fit it was made into a 2 piece skiff. I have made a few this way and it really gives you a big skiff when you anchor up. This skiff has been all over the Atlantic and Caribbean Sea in her lifetime, this being her 6th Atlantic crossing, albeit upside down on deck.

Her first owners retired from sailing and gifted her to me. I gifted her to Tim and Gayle her present owners years ago and with them she is seeing the world. They used to race off road Land Rovers in England and run her the same way…wide open all the time. These little 12’3” designs can handle just about anything in seas and water life except banging against rocks.

Small skiffs can do everything

14 Likes

So, let me get this straight - (assume) wooden skiff, built 32 years ago, still roaming the wild oceans, passed back and forth through various owners. That’s pretty amazing. How long did it take you to build one, start to finish? And, btw, how did the two piece design work? How did it come apart?

Built in solid glass hull matt rove matt rove, core parts in a mold I made. Over 30 built then I designed the #2 version when at HB. I have a #2 version now.

I will post pictures of how to build 2 parts but basically you build the hull, add in the 2 dividing builkheads with an 1/16” pice of paper between them. You build in one first. Drill tiny holes along the dividing edge as reference points to cut in half. Then add paper and set the other bulkhead against this. Build the entire skiff. When finished flip over draw a line from drill hole to hole. Then use a jig saw and cut in half. Now boat will be perfect. There are details on how to bolt together etc that I have refined over the years. It’s all very easy.

With the mold any custom dinghy shape can be built finished in under 40 hours time. If not you can’t make a living.

Building from my plans should take 3 weeks max.

I built quite a few one offs my own dinghy when cruisers I met had to have one. We just took my skiff, took all the hardware off, flipped over, waxed the hull and laid the new hull over my hull. Faired the hulls outside and pulled it off. Inside was now smooth, sand off wax sheen and build interior. Did this all over the place.

People today overthink stuff too much. It’s not that hard just get going…

Average material costs for finished skiffs $1200.00 - $$2400.00

10 Likes

This. I’ve said it more than once.

Who knows the number of boats that were designed at bar, drawn out on cocktail napkins then built the following day by the same two dudes with a hangover.

1 Like

That’s pretty cool, thank you for sharing!

I’d love to have Monte Burke (Lords of the fly) write a book about your adventures.

2 Likes